Extrusion-based Additive Robotic Manufacturing with Living Mycelium Materials

Can additive manufacturing techniques improve the colonisation of the fungi in a given geometry?

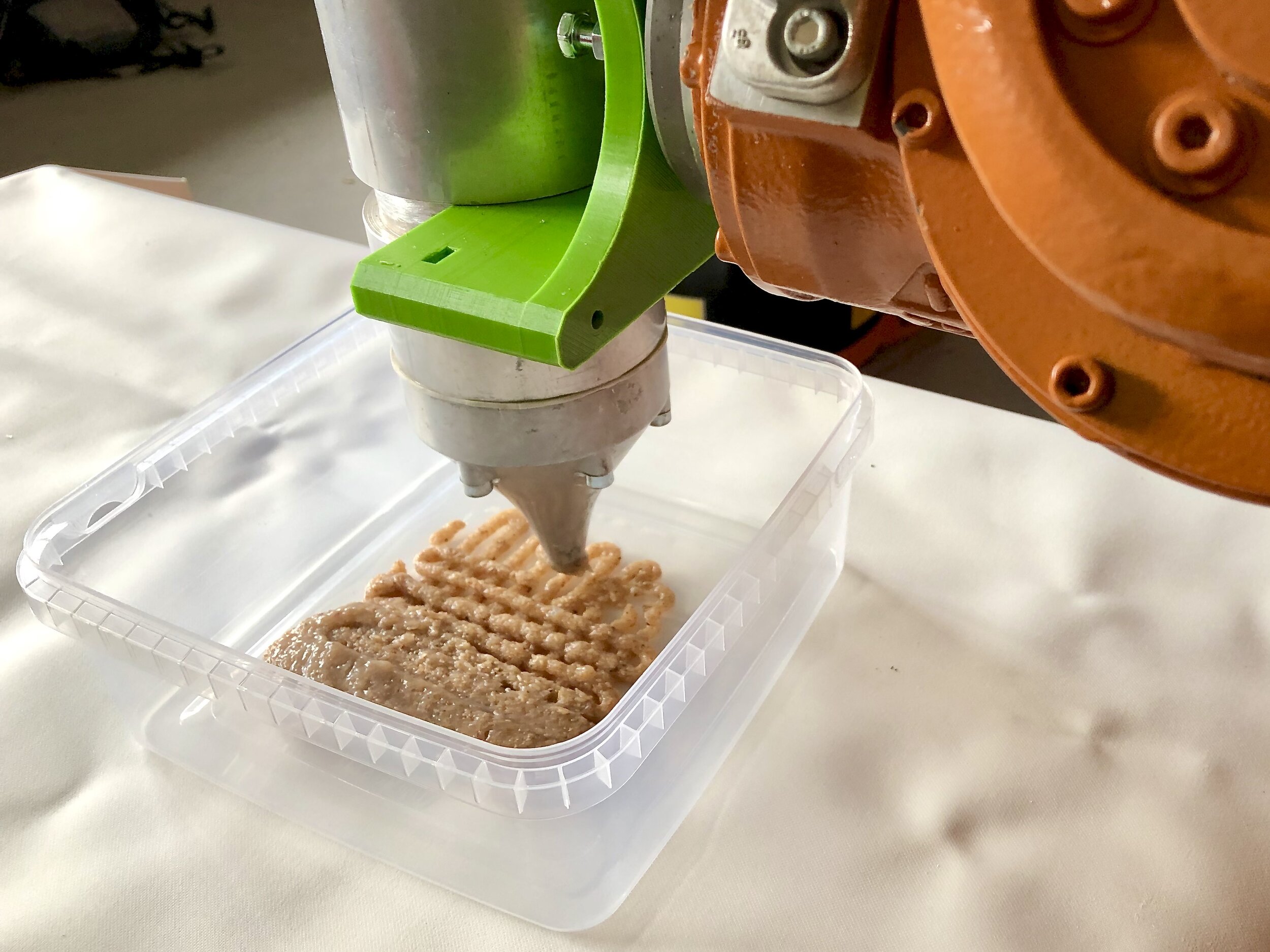

a. Final workflow for living material printing. b. Preparation of the substrate in the laminar flow hood. c. Extruder and printing environment enclosed in a sterile bag. d. Printing in a non-sterile – clean – environment.

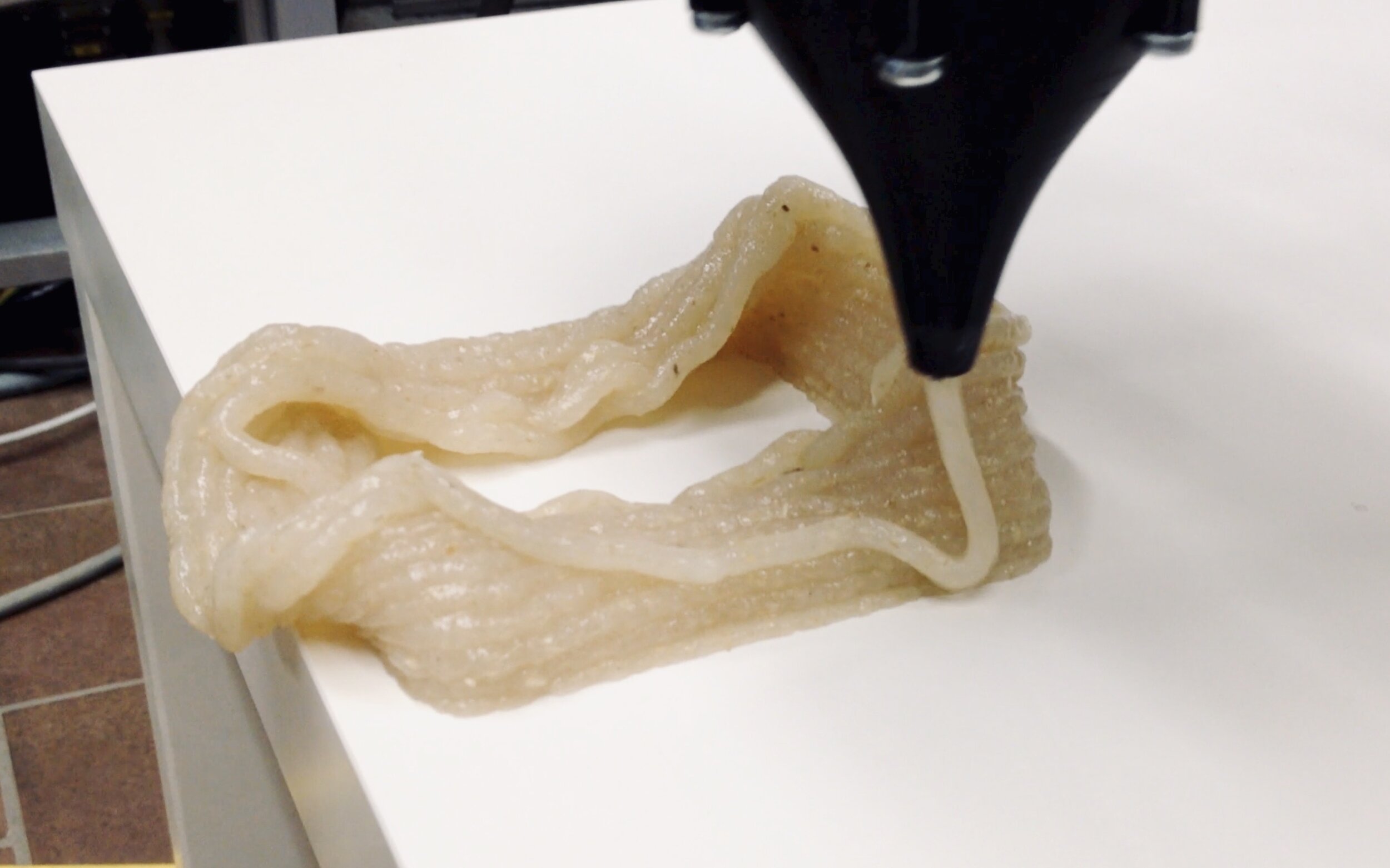

Apart from the wire-cutting fabrication strategy, digital additive manufacturing techniques can also create freeform composites. By 3D printing an extrudable paste, growth functions, such as nutrient, air and moisture distribution, are integrated in the geometry.

Little is known about influence of the manufacturing parameters, conditions during printing process and the relation with the living organism. No previous study has investigated the option of making various substrate compositions, described the material processing, printing parameters, nor developed sterile printing strategies for living extrudable matter. Therefore, in this study, we mapped the advantages and disadvantages of using additive manufacturing in the field of mycelium composites.

Conventional moulding methods presents constrains in term of geometry, uneven oxygen and humidity distribution, which in turn obstruct optimal growth of the organism.

To answer this research question we (1) developed different extrusion systems specific for sterile robotic printing, (2) investigate the various manufacturing processes, (3) describe the emergence of a multi-criteria workflow, (4) explore the rheological, biological and mechanical behaviour of the living material deposition. The purpose was to combine all relevant challenges, processes, production steps, underlying material properties belonging to extrusion-based 3D-printing of biological viscous material.

Given the wide spectrum of complex interrelated variables, the aim was to provide a comprehensive insight based on many empirical experiments which provided a basis to purposefully further shape this novel domain. The work should give some guidance in the technological issues of printing fungal matter at the architectural scale. It disentangles interdepended process variables ranging from the bio-compatibility with the living organism, the robotic fabrication system and hardware, the determination of the printing parameter, the sterile printing process, to some mechanical properties. Our focus was to test the feasibility of 3D printing and from that distil a set of fabrication rules and material constrains and potentialities. We were determined to investigate as many parameters as possible with an empirical, trial-and-error method. Therefore, we developed the extruders ourselves, learned to program a robot from scratch, and experimented with many gelling agents and viscous materials. We made a compilation of learning-by-failing experiments that led us to the further disentanglement of process variables related to the fabrication of mycelium-composites.

Biofabrication masterclass with an architectural engineer, a space engineer, two designers, an artist, an interior architect and two entrepreneurs, organised in collaboration with Glimps.bio and partly funded by a Vlaanderen Circulair grant. (© Photographer Anyuta Wiazemsky).

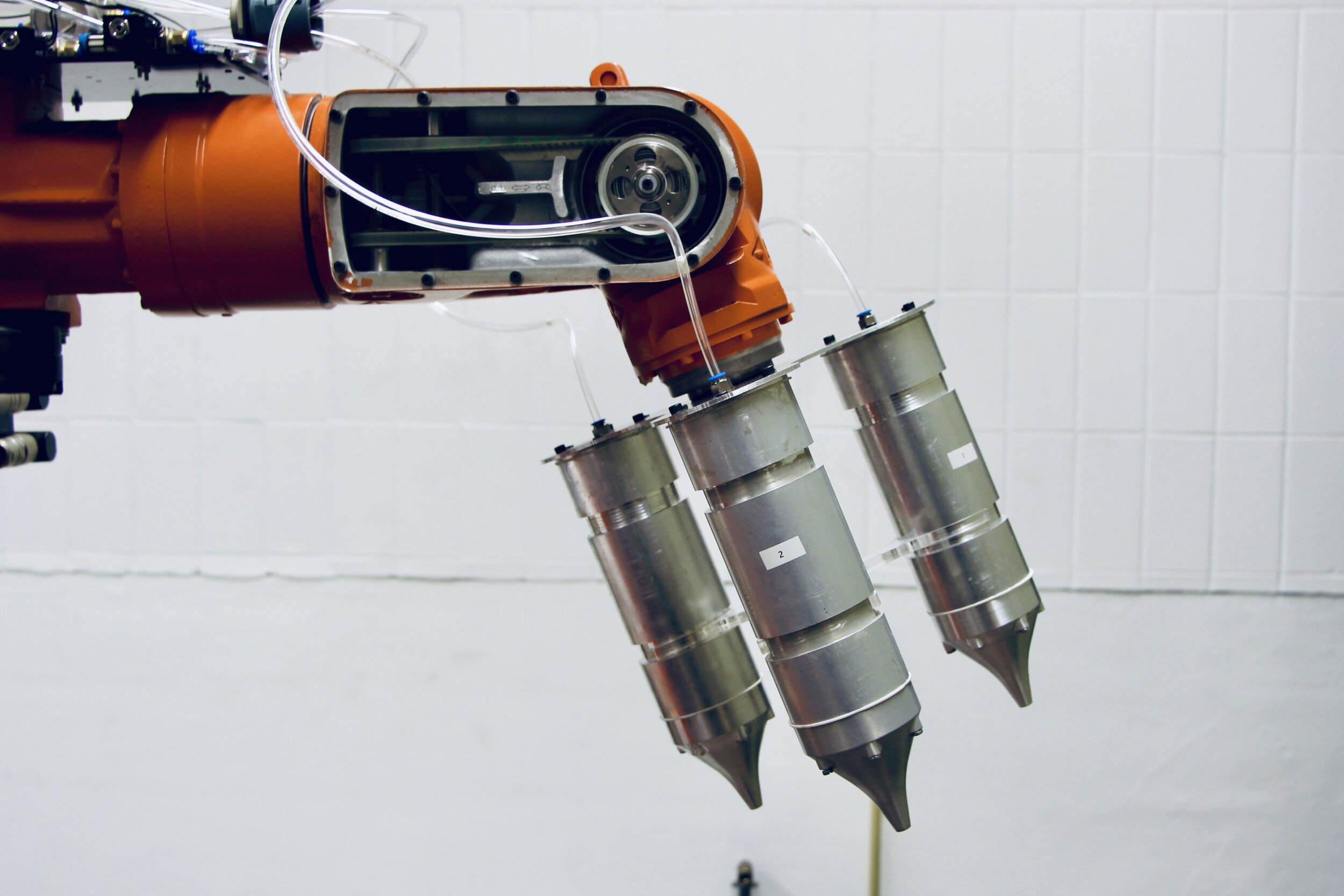

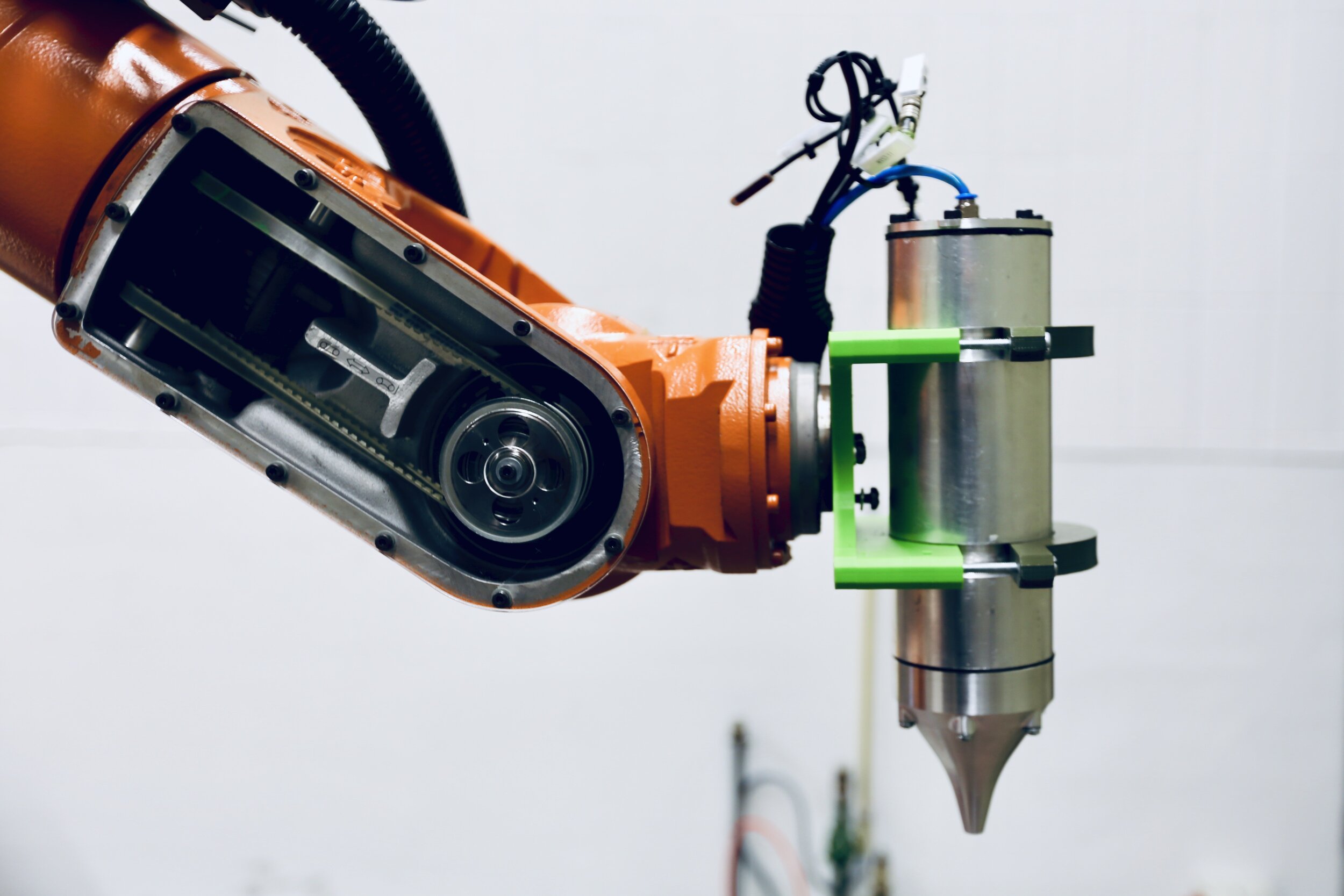

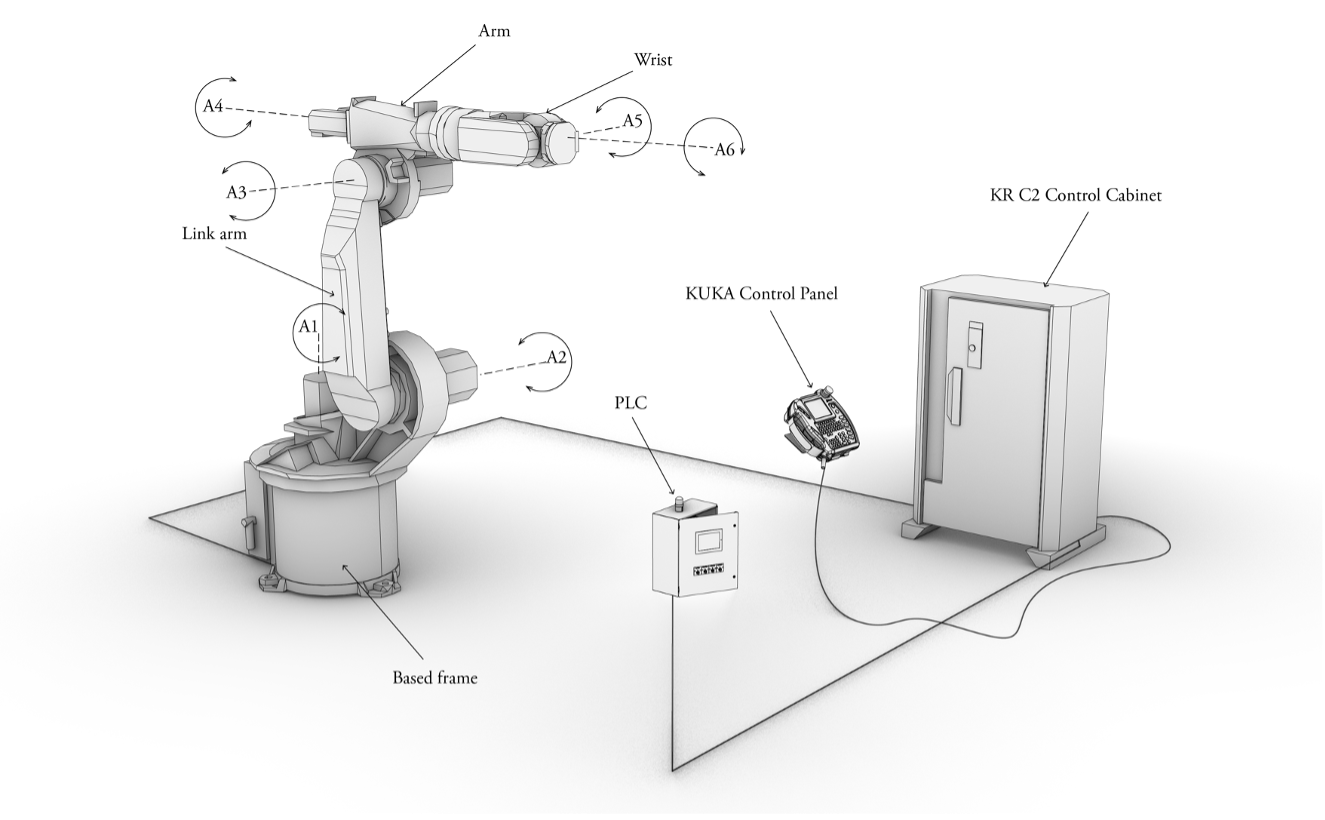

Final assembly of different extrusion systems for printing living matter with a KUKA robot. a-b. Pneumatic single extruder. c-d.Pneumatic static multiple extruder. e-f. Pneumatic movable multiple extruder.

Whether the printing of objects is successful or not depends on the design and type of the extruder. The choice for an extrusion-based (Liquid Deposition Modelling) approach was straightforward since such process already dominate the field of 3D-printing, both in concrete and earth based research as in proof-of-concepts applications. The paste-like substrate lends itself more for extrusion.

A series of design iterations of the fabrication of low-cost extrusion end effector tools was run. All tools were designed and manufactured in-house. The goal was to investigate different ways to extrude the living hydrogel by means of two extrusion strategies, with an auger screw and by pneumatic extrusion.

The requirements for the tool were:

1. Composed of autoclavable materials (resistant to 125°C)

2. Easy to clean and maintain

3. Designed with affordable components and easily machinable parts

4. Allowing printing at room temperature (without heating or cooling element).