Prototype Design: Growth Across 3D-Printed Scaffold Morphologies

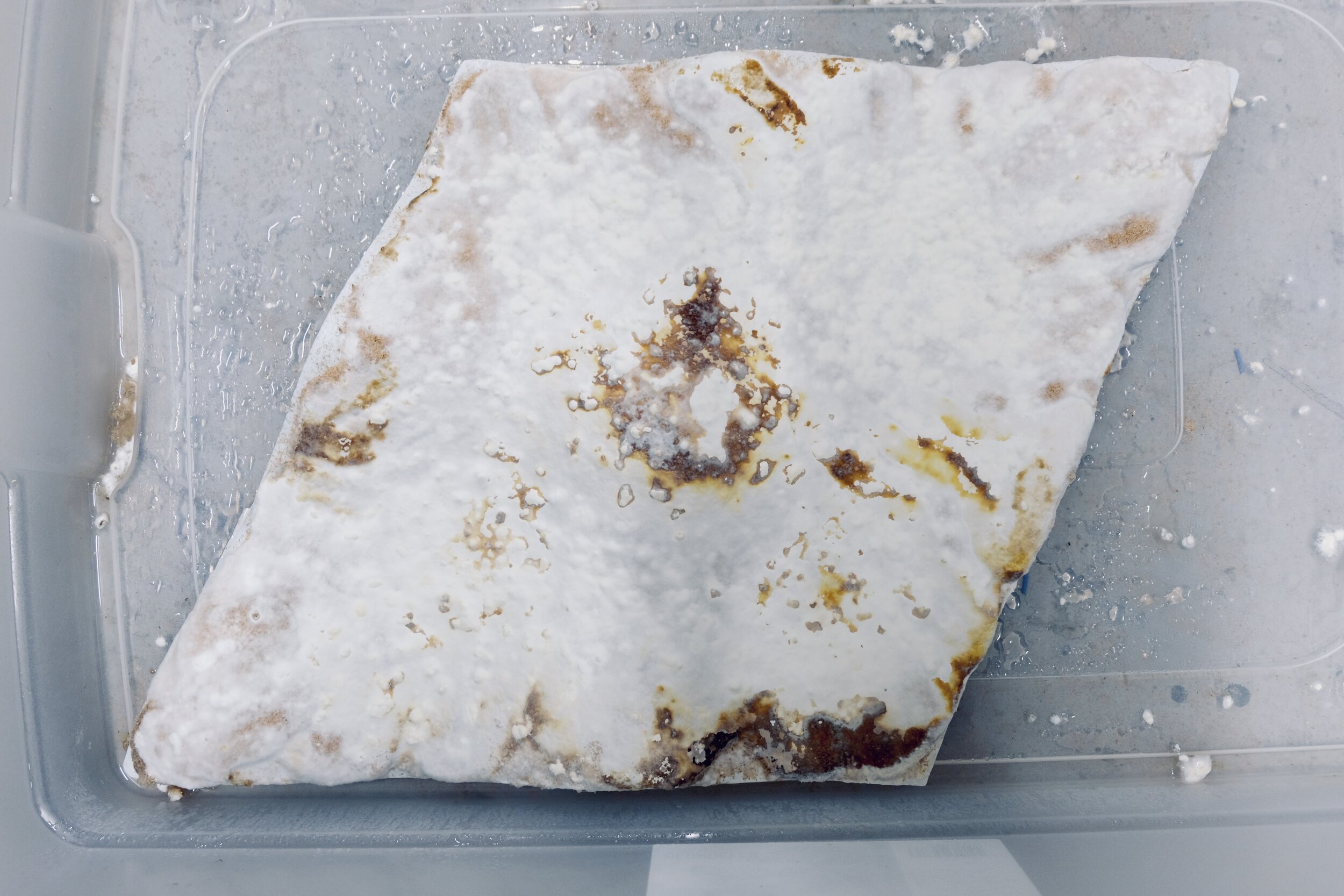

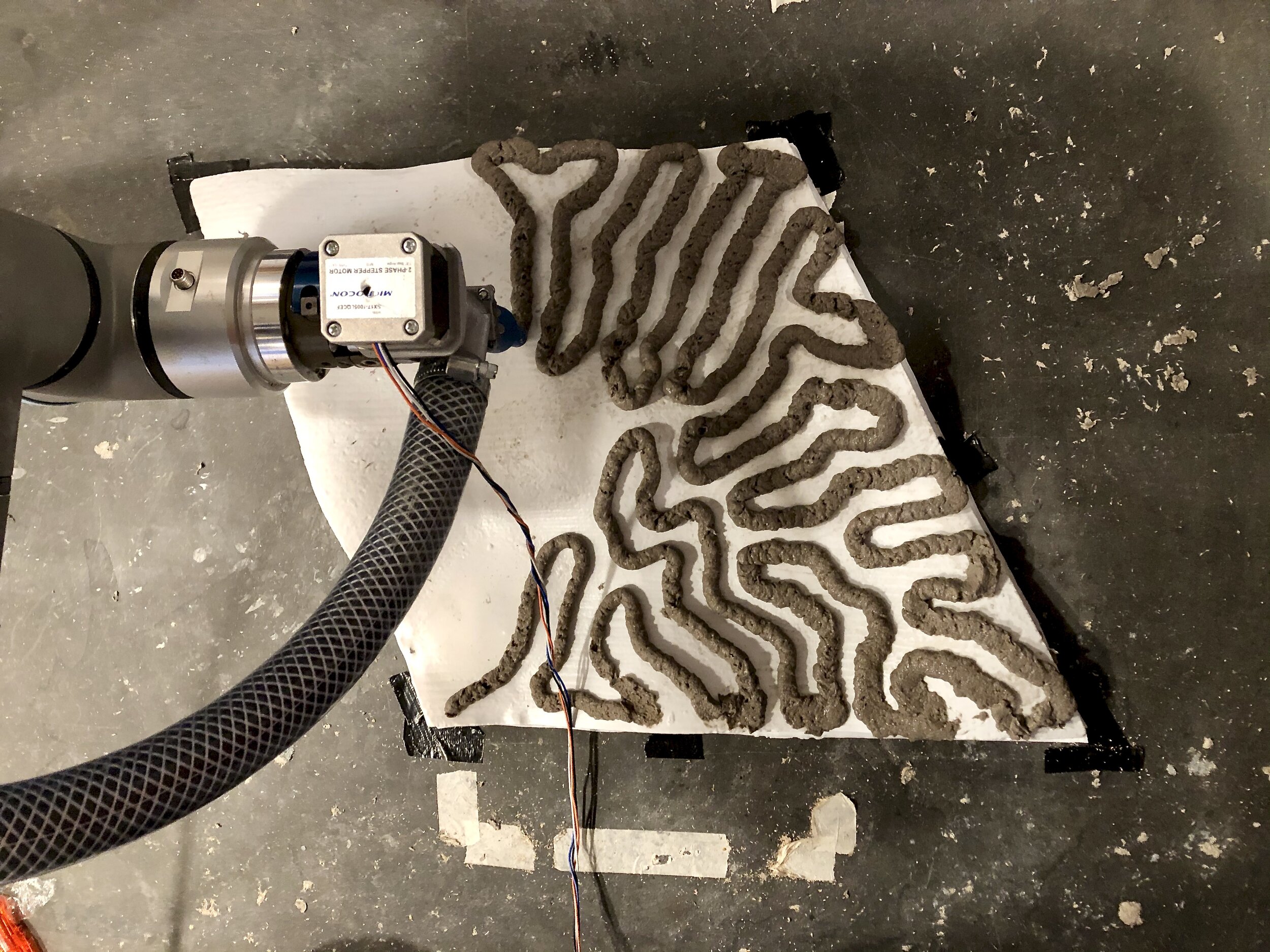

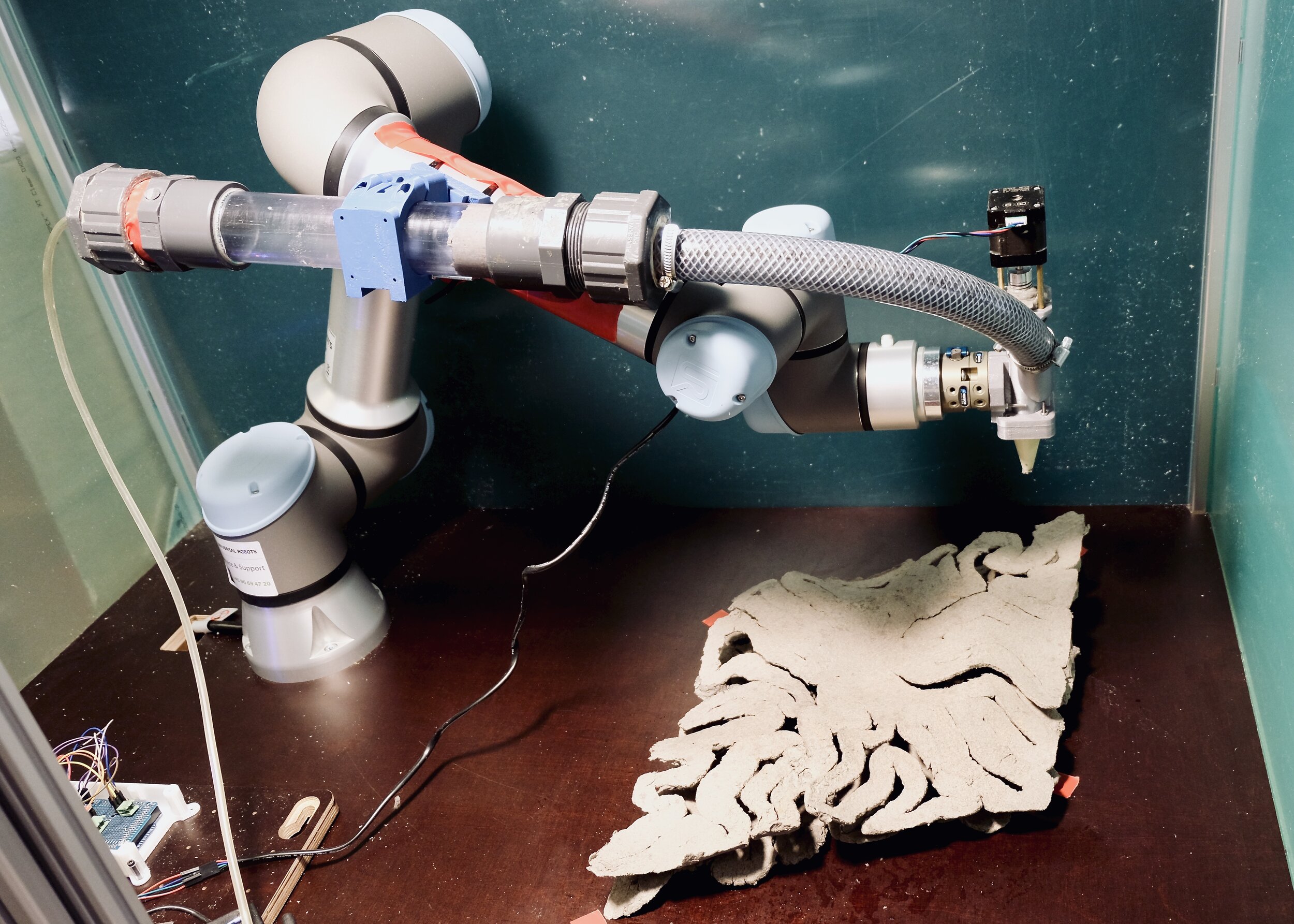

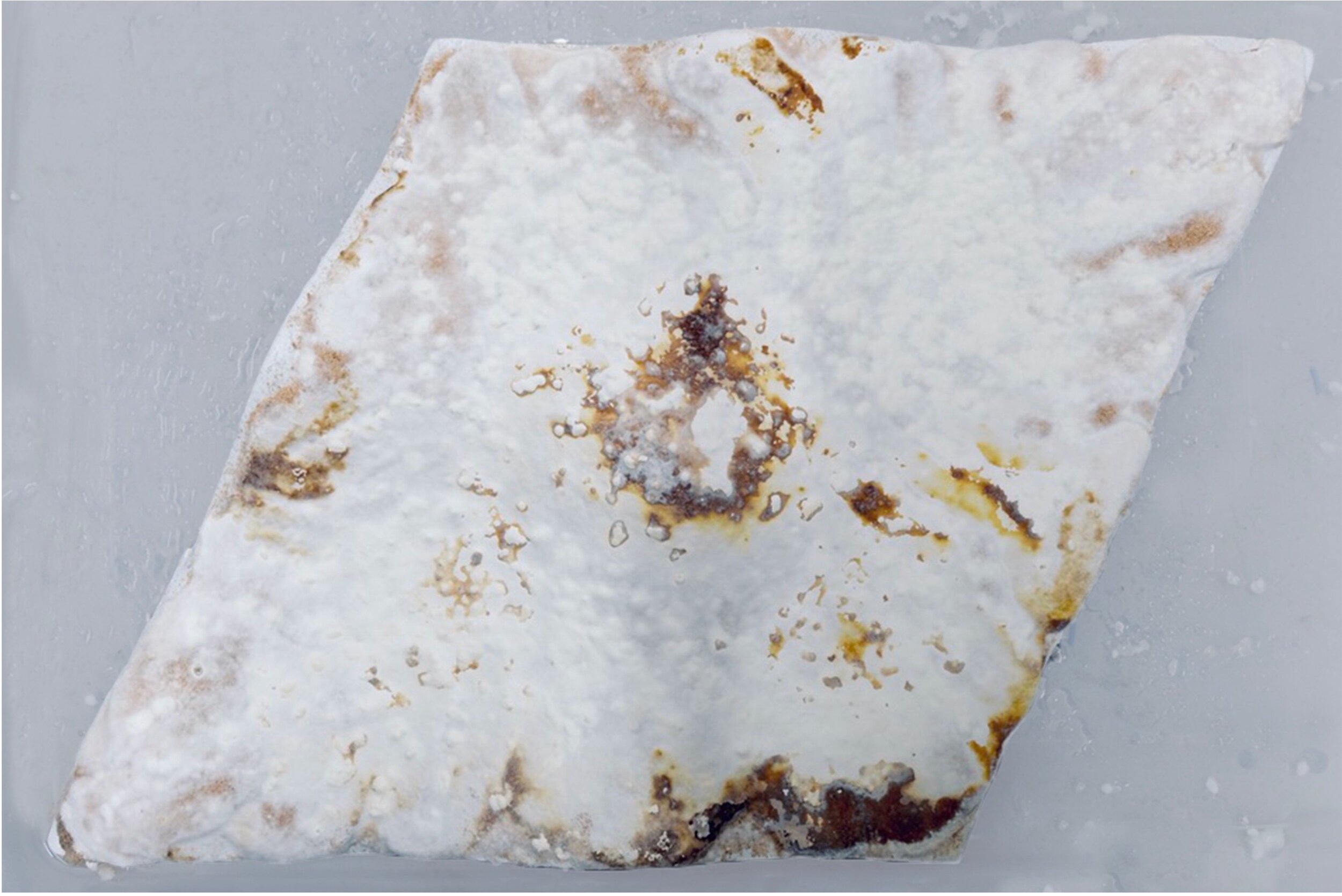

This project explores the creation of biohybrid scaffold morphologies. Instead of printing directly with inoculated mycelium substrate, we approached the additive manufacturing challenges by first depositing the substrate on a double-curved surface as a nutritional landscape for mycelium. This work shows a series of tiles that are 3D-printed with a geometrically complex toolpath based on differential growth patterns. In doing so, air circulation and nutrient access are accommodated all over the surface, increasing the organism’s ability to grow in the core of the material. To provide rigidity, the panels are pressed manually by the negative mould. This experimental method attempts to correlate computational design and robotic fabrication with mycelium growth. It can perhaps yield a more holistic picture of the potential of new fabrication technologies with mycelium materials.

This work was done during my research stay at CITA (Centre for Information Technology and Architecture, at KADK) in Copenhagen, Denmark.

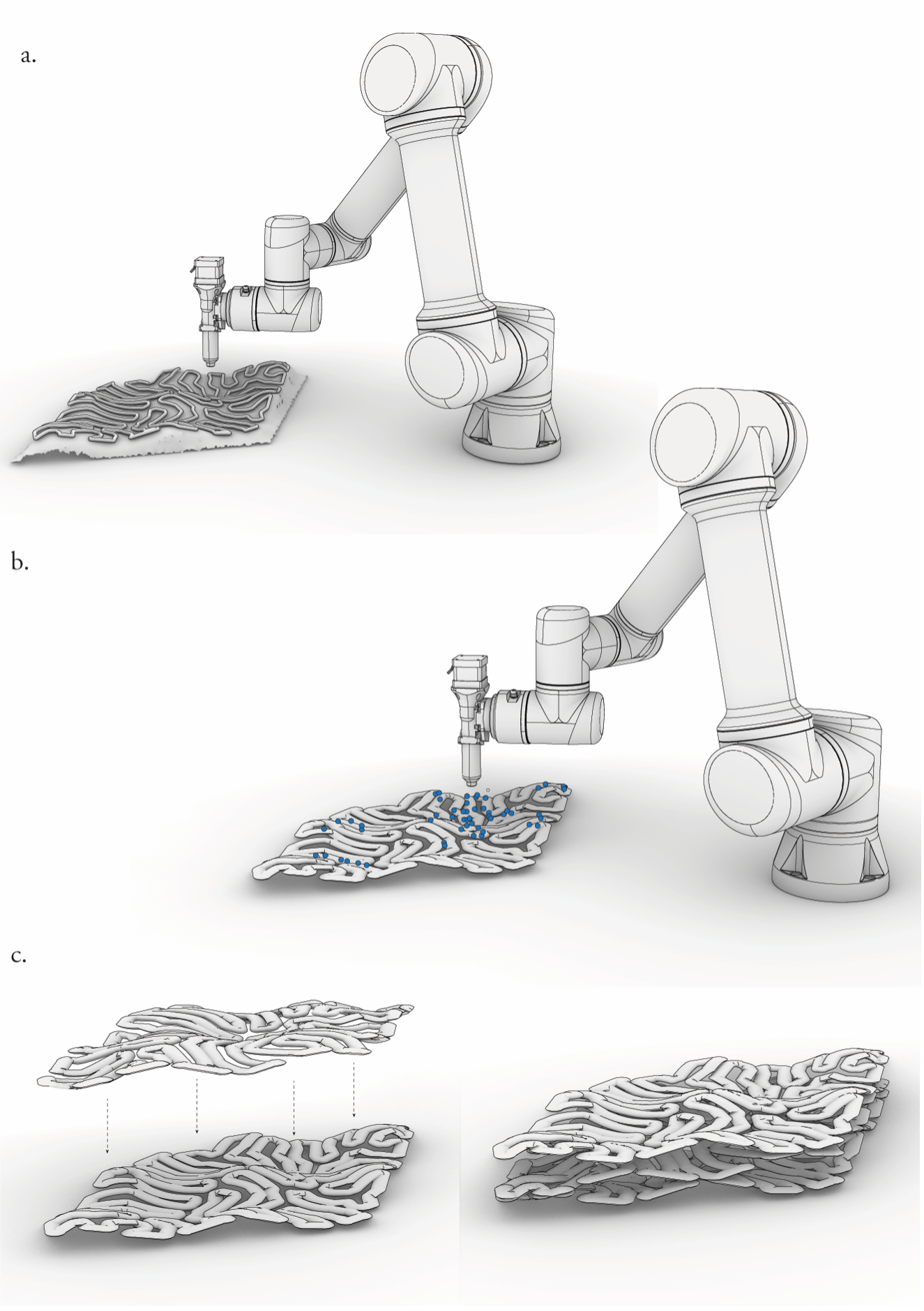

Schematic diagram of the experimental proofs-of-concepts. a. Depositing viscous substrate on a 3D-formwork. b. Inoculating dried and compressed tile with the fungi. c. Stacking different bio-scaffolds to form the final object.

Acknowledgements

This research was made possible thanks to the funding of the SB Fellowship of the Research Foundation Flanders [grant number 1S36417N (E.E.)]. The work was supplementary supported by an FWO long term travel grant [grant number V442219N] which financed my research stay at the Centre for Information Technology and Architecture (CITA), the Royal Danish Academy of Fine Arts Schools of Architecture, Design and Conservation.

Citation

Elsacker, E. (2021). Mycelium matters - an interdisciplinary exploration of the fabrication and properties of mycelium-based materials. VUBPRESS.